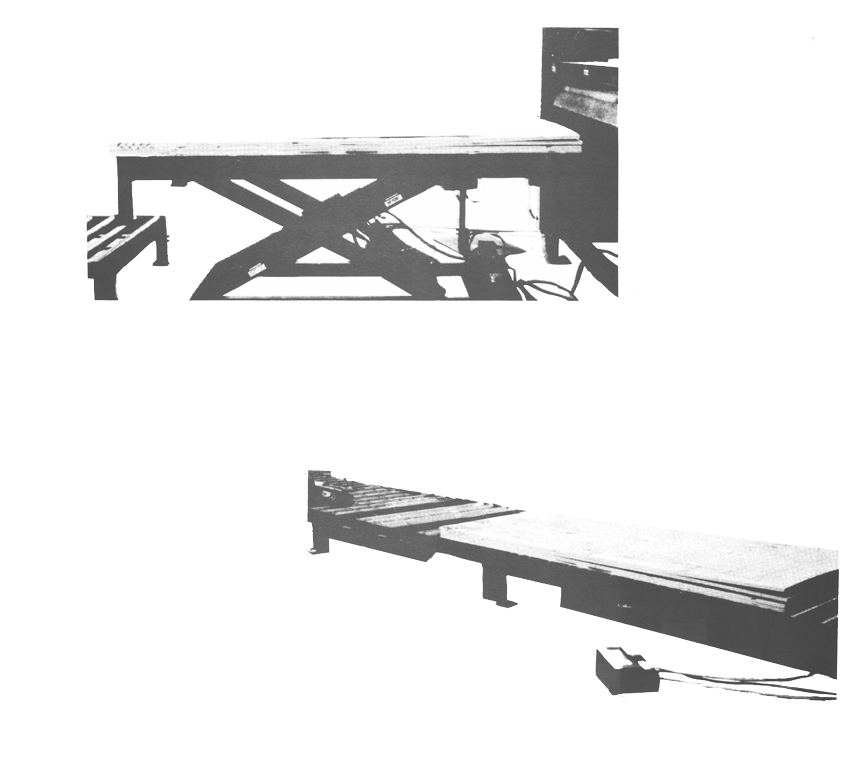

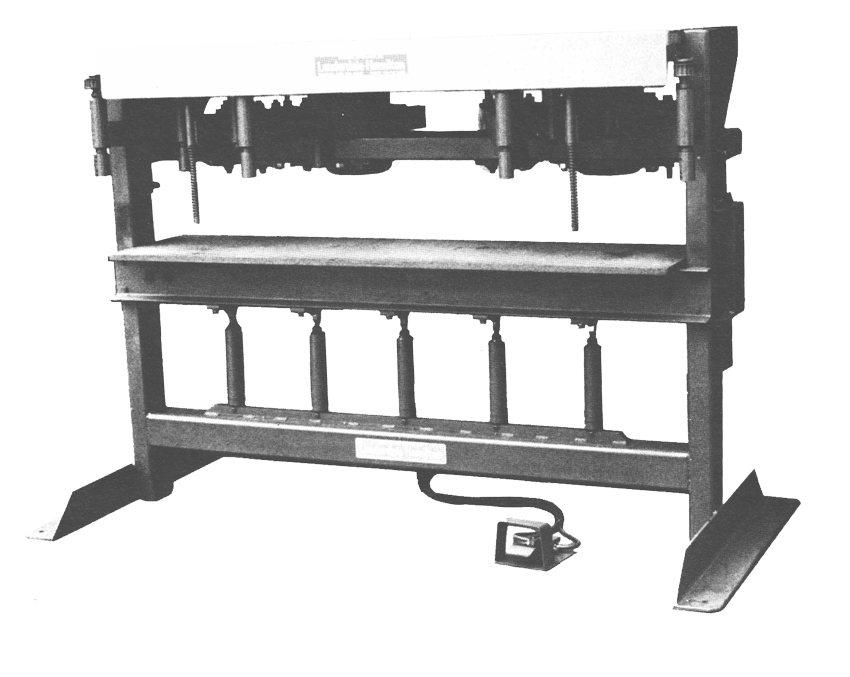

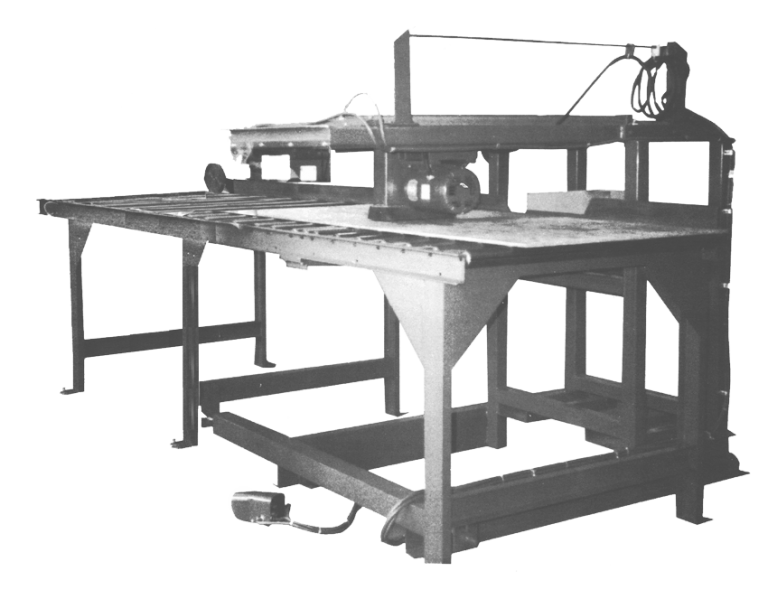

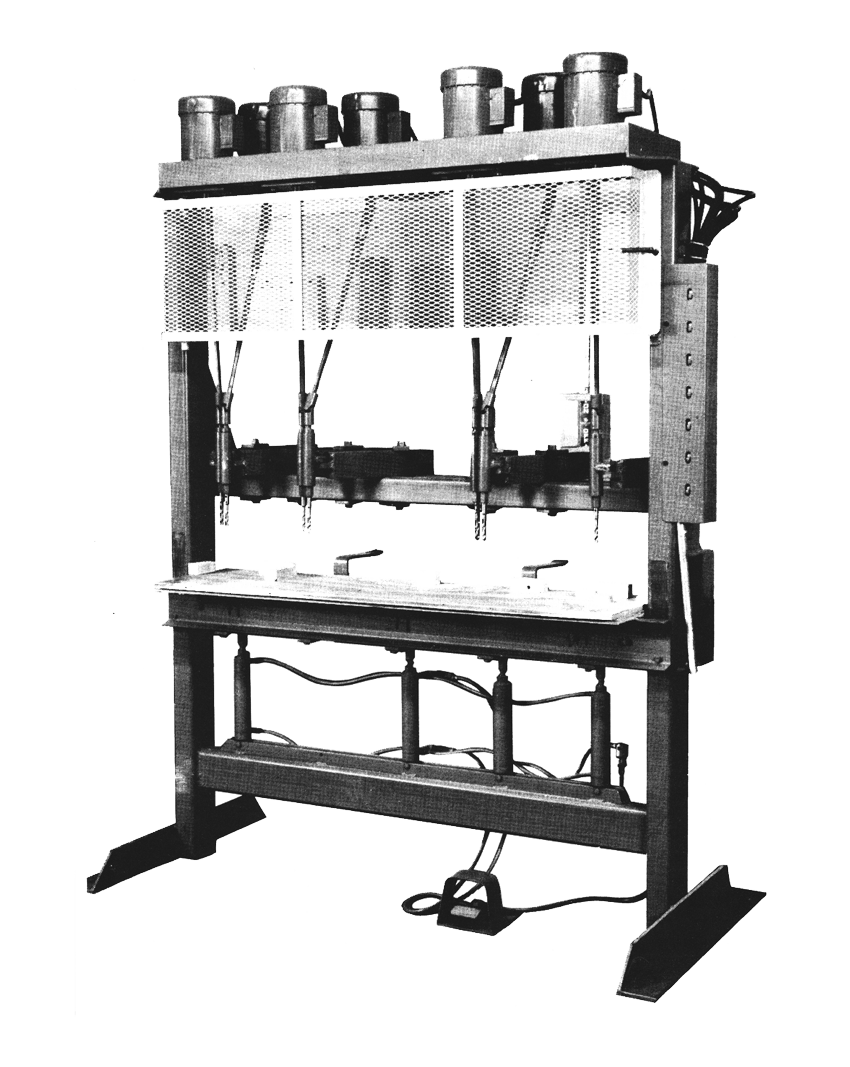

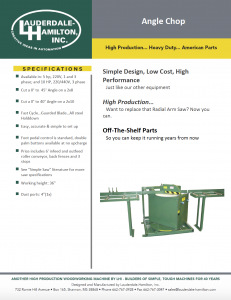

HIGH PRODUCTION...HEAVY DUTY...AMERICAN PARTS

Simple Design, Low Cost, High Performance

Just like our other equipment

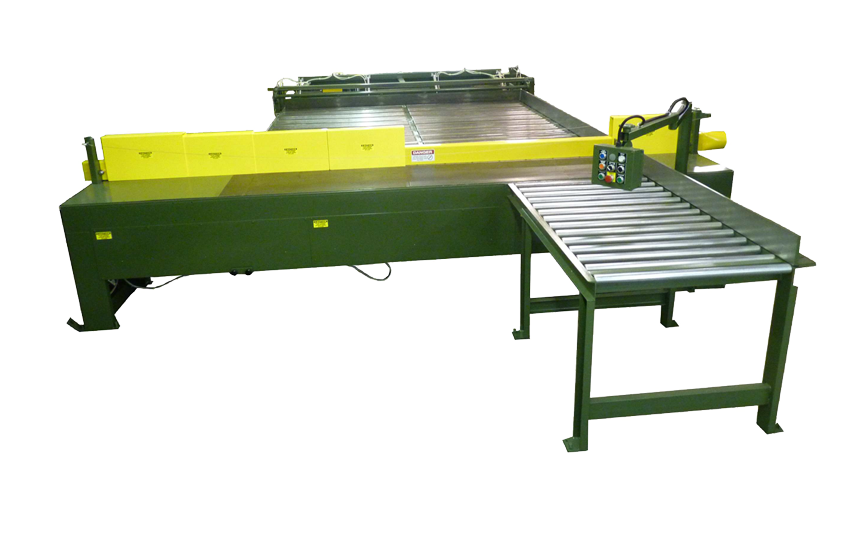

When it's up, it’s a stable, 4000lb lift

Feed onto it or off of it

When it's down, it’s a conveyor

Stage your next bundle in or out without the need for a fork lift